Solution Manufacturing Process II 2022

Solution Manufacturing Process II 2022

Multiple Choice Questions

i. In shaper machine, the tool always – a) remains stationary b) rotates c) reciprocates d) none of these

Answer: c) reciprocates

Explanation: In shaper, a single point cutting tool is used to remove materials layer by layer from the surface of the work piece, such that the reciprocating motion is provided to the tool, with the help of Quick-Return Mechanism.

ii. Size of shaper is given by – a) power of motor b) feed rate c) stroke length d) weight of the machine

Answer: c) stroke length and d) weight of the machine (both are correct but option a is more accurate)

Explanation: The size of a shaper is specified by – length of stroke or cut, type of drive (belt drive or motor drive), floor space required, weight of the machine, cutting to return stroke ratio, number and amount of feed, power input.

iii. Saddle movement of shaper is obtained by – a) cross feed screw b) guide ways c) tool reciprocation d) vertical reciprocation

Answer: ??

iv. The depth of cut in drilling is – a) one-half of drill diameter b) one-fourth of drill diameter c) equal to drill diameter d) double of drill diameter

Answer: a) one-half of drill diameter

Explanation: the depth of cut in drilling operation (through drilling) is taken as half of the drill diameter, if cutting Speed and Feed (mm/rev) is not provided in a case.

v. Drilling is an example of – a) orthogonal cutting b) oblique cutting c) uniform cutting d) complex cutting

Answer: b) oblique cutting

Explanation: Drilling is an oblique cutting process because the major cutting edge of the tool is presented to the work piece at an angle less than 90 degree, to the direction of feed motion.

vi. Five motions of table can be achieved in – a) Plain Milling Machine b) Universal Milling Machine c) Omniversal Milling Machine d) Vertical Milling Machine

Answer: c) Omniversal Milling Machine

Explanation: In ‘Omniversal Milling Machine’ the table has all the four movements of a universal milling machine (i.e. longitudinal movement, cross-movement, vertical movement, and rotation about a vertical axis), the fifth movement is rotation about a horizontal axis parallel to the spindle.

vii. The cutting edges of a standard twist drill are called – a) Lips b) Flutes c) Flank d) Wedge

Answer: a) Lips

Explanation: The lips, also known as cutting edges, are the edges formed by the intersection of flanks and faces.

viii. For grinding softer material the grade of the wheel should be – a) soft b) medium c) hard d) brittle

Answer: c) hard

Explanation: For grinding softer material, hard grinding wheel is used, if a hard grinding wheel is taken for grinding a hard work piece, the rubbing force increases & abrasive particles wears out quickly, and no metal removal will take place (glazing) and only rubbing action will persist.

ix. Which of the following operations needs to be performed to obtain surface finish of the order of 0.75 to 1.30 µm: a) honing b) lapping c) buffing d) grinding

Answer: ??

x. The feed direction and direction of rotation of cutter are in opposite direction in – a) up milling b) down milling c) profile milling d) saw milling

Answer: a) up milling

Explanation: the direction of rotation of cutter and feed direction of the workpiece is opposite in case of up milling.

xi. In gear hobbing – a) only hob rotates b) only gear blank rotates c) both hob and gear rotate d) no such rotation

Answer: c) both hob and gear rotate

Explanation: In gear hobbing the gear blank wheel is rotated against a rolling cutter.

xii. When more than two cutters are involved at a time, the milling process is termed as – a) gang milling b) saddle milling c) angular milling d) face milling

Answer: b) saddle milling

Explanation: In straddle milling, two side milling cutters are used at the same time.

xiii. Gear burnishing is a process for – a) surface finishing b) heat treatment c) gear finishing d) buffing

Answer: a) surface finishing

Explanation: Burnishing is a mechanical surface finishing process used to improve the surface finish, improves wear resistance, enhanced fatigue strength, of a workpiece by compressing the material at the surface layer.

xiv. What is the symbol of resinoid bond among the following? a) R b) B c) E d) O

Answer: b) B

Explanation: According to Indian Standard marking system (IS: SS1-1954) in a grinding wheel B stand for Resinoid, R stand for Rubber, E stand for Shellac, S stand for Silicon, O stand for Oxychloride type of bond. The bond denotes the bond between the abrasive grits and the body of the grinding wheel.

xv. The magnesium powders for pyrotechnic applications are produced by – a) crushing b) grinding c) machining d) atomization

Answer: d) atomization

Explanation: Magnesium powders used in pyrotechnic applications are typically produced by a technique called atomization. Atomization involves spraying molten magnesium into a gas stream where it solidifies into fine droplets that quickly solidify into powder as they cool.

Fill in the blanks Questions

i. In a shaper, the tool post is mounted on _____________.

Answer: Reciprocating Ram.

ii. For moving the table in vertical direction, ____________ is used.

Answer: elevating screw (in shaper)

iii. Return stroke in shaper is also known as __________.

Answer: idle stroke

iv. When the ram reciprocates in vertical direction, it is also known as _____________.

Answer: vertical shaper

v. Low helix angle drills are used for drilling holes in _______________.

Answer: brass

vi. In drilling operation, the metal is removed by ___________.

Answer: major cutting edges

vii. The process of producing coarse powder with high % of oxide is ____________.

Answer: granulation

viii. A grinding wheel gets glazed due to _____________ of abrasive grains.

Answer: wear

ix. For truing of grinding wheels, the required tool material is ___________.

Answer: diamond pointed tool

x. Helical gears can be cut on _____________ type of milling machine.

Answer: universal milling machine

xi. Dividing periphery of work piece into any number of equal divisions is called ___________.

Answer: indexing

xii. Filtering the pores of sintered part with molten metal is called _____________.

Answer: Infiltration

xiii. Combination of face milling and peripheral milling is known as __________.

Answer: End milling

xiv. Plain milling operation is also called ____________.

Answer: slab milling or peripheral milling

xv. Honing is a _____________ velocity abrading process.

Answer: low

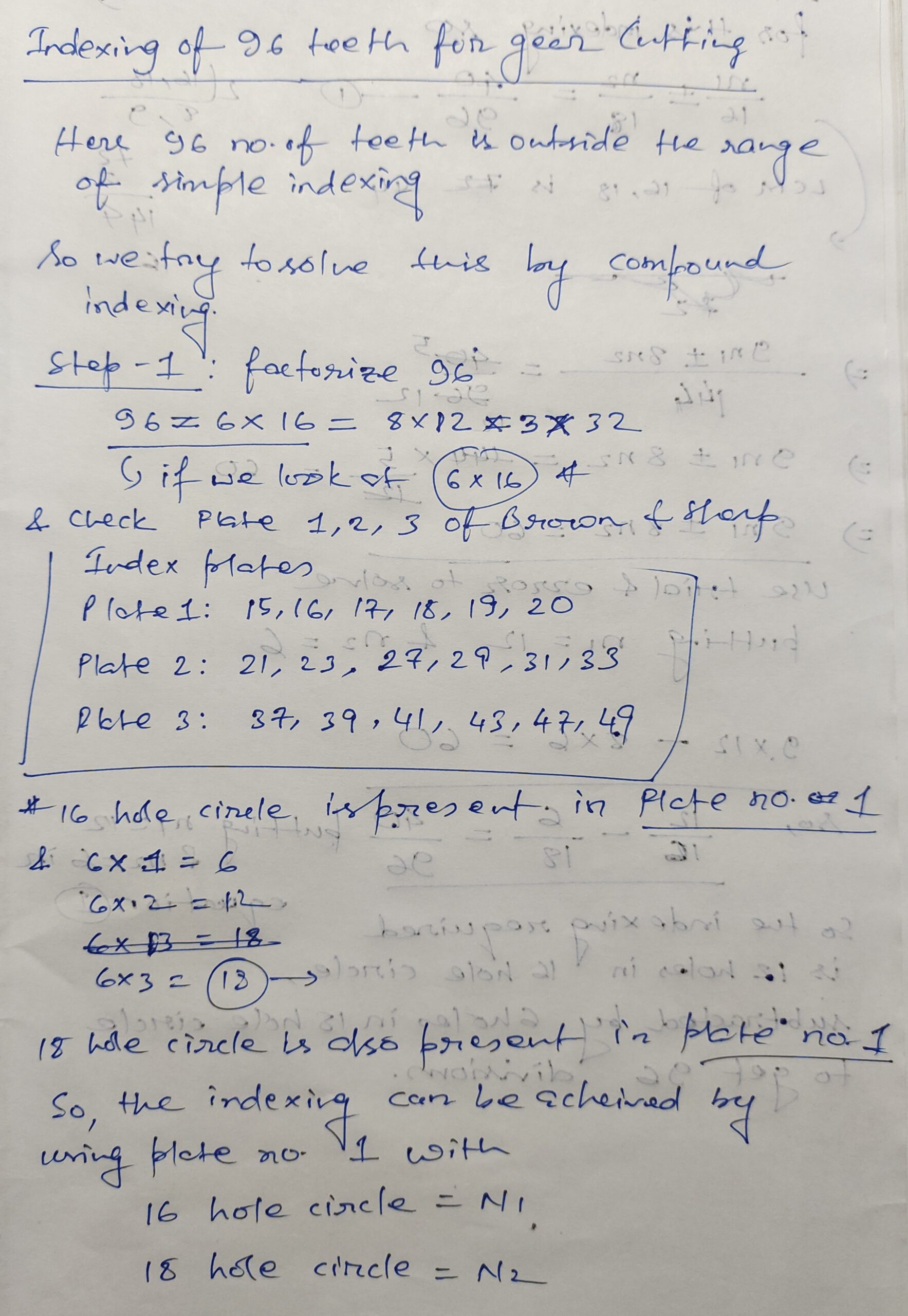

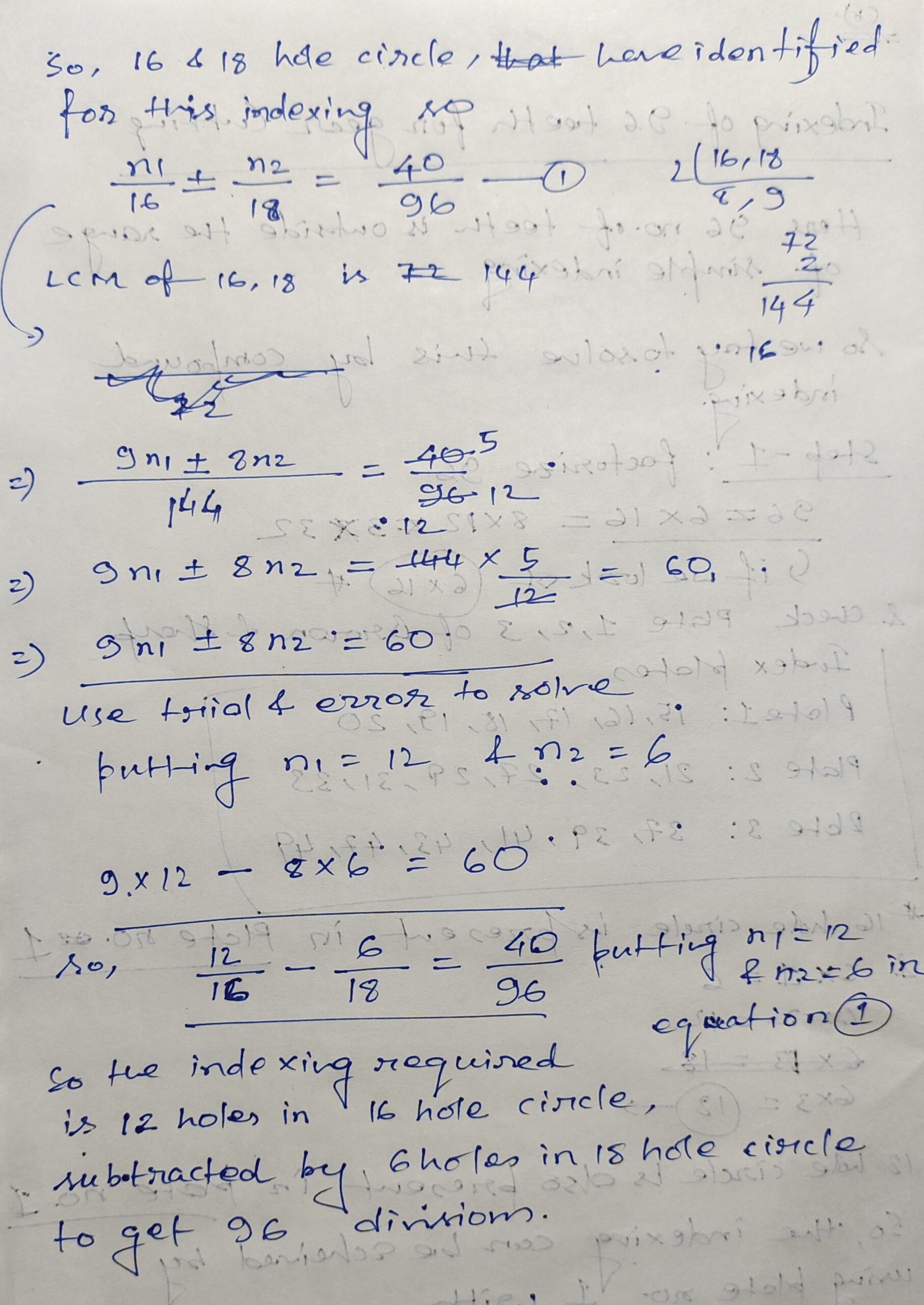

3. Indexing of 96 teeth for gear cutting. [WBSCTE 2022, 2023]